We are using the most advanced technologies

read moreOur experts

We are not afraid to meet up with difficult tasks

„We are open to implementing state-of-the-art production technologies, therefore we are not afraid of new challenges. We invest in the high competences of our team, at the same time continuing to develop our machinery park. ”

Michał Kołodziejczyk, Production Director

Our experts

The key to proper implementation is information

„Holding the full technical documentation from the client makes our work smooth and efficient. The ease of translating the design into a prototype or complete production batch is directly proportional to the amount of information we receive at the initial project phase.”

Tomasz Kielar, Production Preparation Director

Our experts

Alert at every production step

„The one phrase we hear quite often in projects is "due yesterday". When working on changing projects and under time pressure, I manage production in a way allowing me to respond to unexpected and unplanned events in an agile manner, at every step of the already commenced process.”

Sławomir Kafel, Head of Production

Our services

We offer the most advanced tools to suit your needs

Comprehensive project management

Metal sheet processing

Wire processing

Pipe and profile processing

Machining

Welding

Joining technologies

Surface preparation

Surface finish

Assembly and packaging

Logistics

Quality control

Comprehensive project management

The smooth implementation of projects is ensured by our team of specialists

14 project managers

19 designers and process engineers

When performing projects, we use tools such as: CDN XL, IPO SYSTEM, SOLID WORKS, as well as AUTOCAD, allowing us for complete optimization of the process.

CDN XL

IPO SYSTEM

SOLID WORKS

AUTOCAD

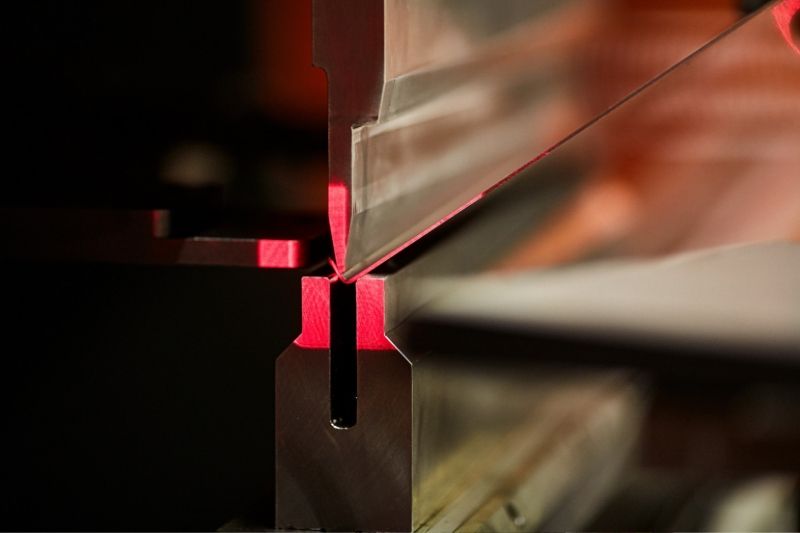

Metal sheet processing

Our state-of-the-art equipment allows us to produce complex and complicated workpieces, at the same time ensuring repeatability of the operations.

We offer

• laser cutting and punching of sheet (2 FIBER type lasers, and COMBI integrated device for laser cutting and punching),

• as well as sheet bending (we work on 6 bending brakes, including ones with laser angle measurement, and on 3 bar folders).

Wire processing

Thanks to the automated cutting process, we produce workpieces with high accuracy and repeatability.

We work on 2 stations with numerically-controlled 3D bending centers, and 5 eccentric presses as well.

Pipe and profile processing

We perform laser cutting of 2D shapes, and bending in 3 dimensions. Owing to the automation and programming of every workpiece, we achieve excellent repeatability of production.

We offer laser cutting of sections (FIBER laser) as well as bending and coiling of shapes (automated CNC bending center + coiler).

Machining

We offer machining on 2 multi-axis machining centers.

2 multi-axis machining centers.

Welding